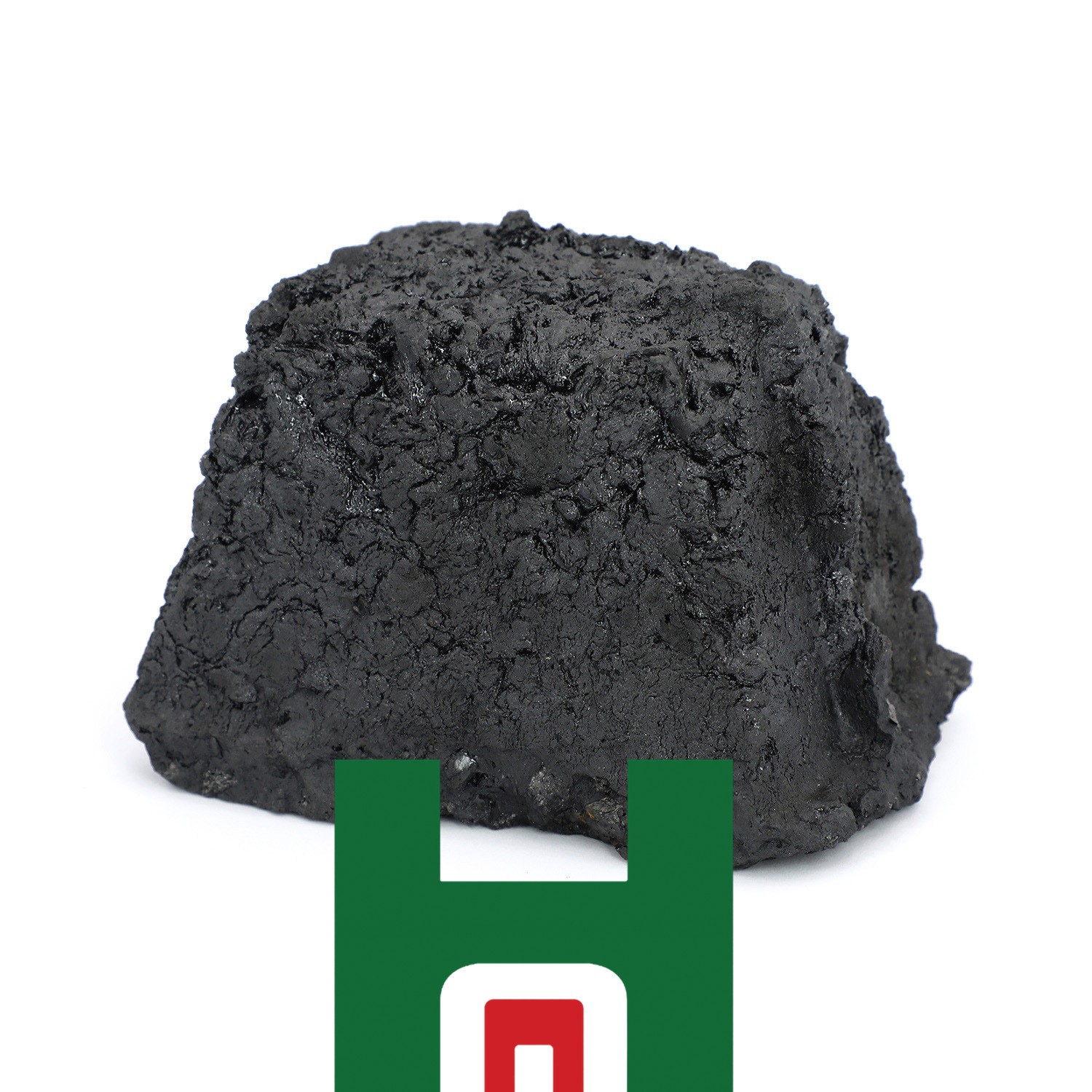

Carbon Electrode Paste for Ferronickel Ferrosilicon Smelting Furnace

Brand HQ

Product origin Shandong

Delivery time 7-15 days

Supply capacity 150,000tons

Carbon electrode paste is a self-baking electrode used in submerged arc furnaces for delivering power to the charge mix. Electrode Paste is added to the top of the electrode column in either cylindrical or briquette form.

Product Description

| Item | Electrode Paste | ||

| Si | <0.28% | Fe | <0.25% |

| P | <0.004% | ||

| Ash Content | 2-10% | Resistivity | 55-90 uΩm |

| V.M | 10.0-15.0% | Density | >1.46g/cm3 |

| Compression Strength | >18Mpa | Extensibility | 6-20 |

| Apparent Density | >1.42g/cm3 | Rupture Strength | >4.0 |

| Real Density | >1.98g/cm3 | Fluidity Coefficient | 1.10-2.10 |

About performance of carbon electrode paste

Low resistivity– to reduce the power loss when the current passes through the electrode; The thermal expansion coefficient is small, which ensures the internal stress caused by the abrupt temperature change will not cause the electrode to produce small cracks and increase the resistance; The smaller porosity ensures a smaller contact area with oxygen, thereby prolonging the oxidation process of the electrode in the heating state. Meanwhile, the increase in electrode strength and conductivity makes both the resistance and the electrical loss small; High mechanical strength –to prevent the electrode from broken due to mechanical and electrical loads; The ash content is a strict control index of the carbon electrode paste, which directly decides the sintering quality of the electrode, and has a great influence on the conductivity, oxidation resistance and sintering density of the electrode. The ash content of electrode paste produced by our company is as low as 3%, the consumption is very low, and other indicators are also very good. It is especially suitable for large submerged arc furnace.

Packaging & Shipping

Packing Details: 25kg small bags or 1mt jumbo bag

Port: Tianjin Port, Qingdao Port

Leading Time: Shipped in 15-30 days after payment

Company Profile

Rizhao Hengqiao Carbon Co.,Ltd is located in Rizhao City, one port of Shandong Province, which is specialized in exporting varieties of cokes in China , including Graphite Electrode , petroleum coke, calcined coke, graphite petroleum coke and so on.

Exhibitions

Certifications