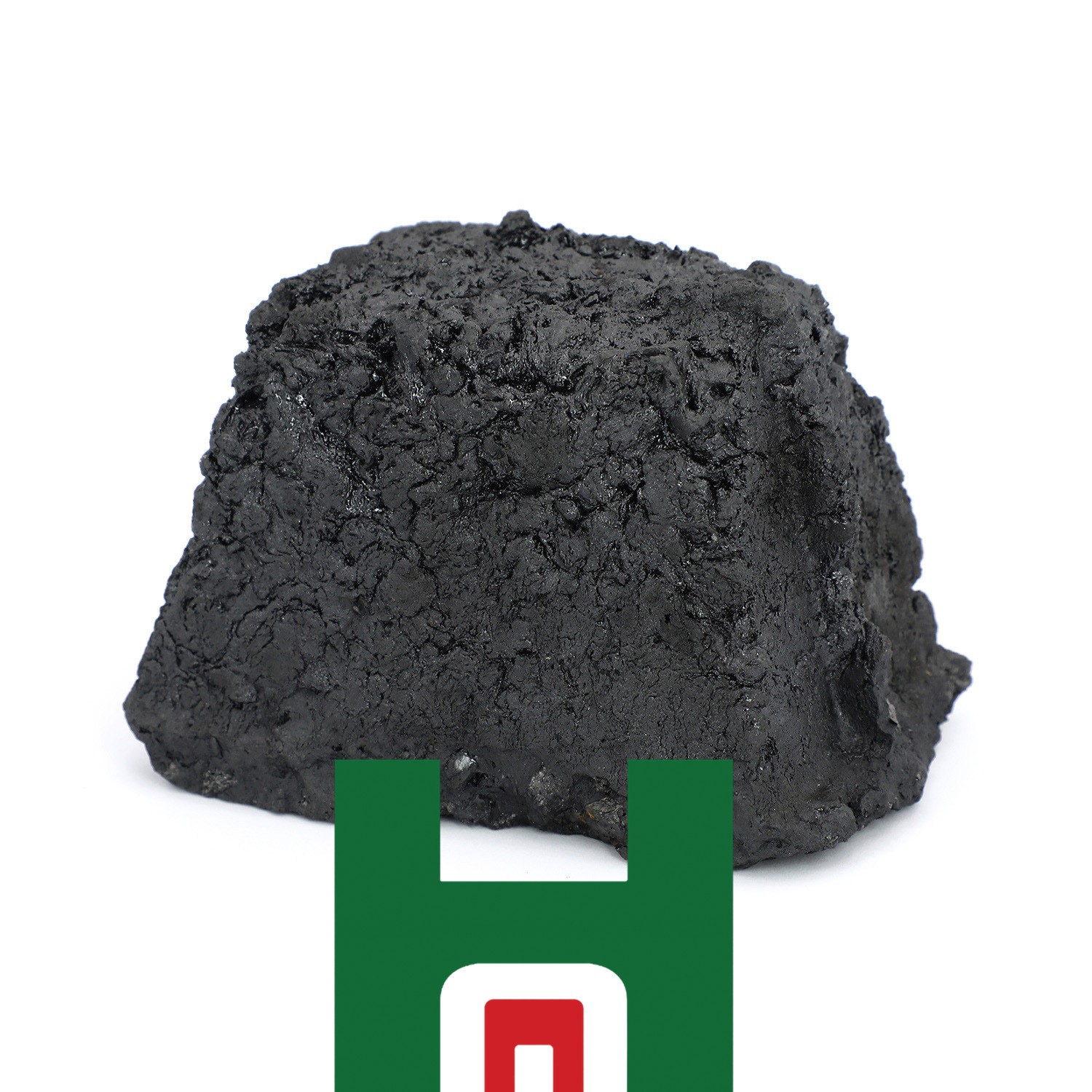

High Quality Cold Ramming Paste Carbon Electrode Paste Self Baking Electrode Paste for Furnace Linings

Brand HQ

Product origin Shandong

Delivery time 7-15 days

Supply capacity 150,000tons

Carbon electrode paste is used as self-baking electrodes for submerged arc furnaces,it’s a kind of carbon products,consisting of ECA,CPC and graphite powder, with the coal tar pitch as the binder,after the mold shaping.

Product Description

| Item | Carbon Electrode Paste | ||

| Si | <0.28% | Fe | <0.25% |

| P | <0.004% | ||

| Ash Content | 2-10% | Resistivity | 55-90 uΩm |

| V.M | 10.0-15.0% | Density | >1.46g/cm3 |

| Compression Strength | >18Mpa | Extensibility | 6-20 |

| Apparent Density | >1.42g/cm3 | Rupture Strength | >4.0 |

| Real Density | >1.98g/cm3 | Fluidity Coefficient | 1.10-2.10 |

The manufacturing process of carbon electrode paste involves the careful selection of high-quality raw materials, primarily petroleum coke and coal tar pitch. These materials are chosen for their purity, carbon content, and specific characteristics. The selected components are blended in precise proportions, creating a homogeneous paste.

The mixing stage is followed by kneading, where the paste is shaped into a consistent and workable form. The next step involves extrusion or vibration molding to produce the desired shape and size of the electrode paste. This formed paste undergoes baking or calcination at elevated temperatures, typically exceeding 1000 degrees Celsius, to ensure the removal of volatile components and enhance the final product's mechanical strength and electrical conductivity.

The final electrode paste is then packaged for use in various industrial applications, including electric arc furnaces in steelmaking and other processes requiring a reliable and conductive carbon source. The entire manufacturing process is designed to produce a high-quality carbon electrode paste tailored to meet specific industrial requirements.

Packaging & Shipping

Packing Details: 25kg small bags or 1mt jumbo bag

Port: Tianjin Port, Qingdao Port

Leading Time: Shipped in 15-30 days after payment

Company Profile

Our product mainly sells to Middle East, North America, South America, Eastern & Southern Europe, South & Southeast Asia, Africa and so on. Because of our "win-win" belief, we have established long-term cooperation with many customers overseas for many years. If you want to enjoy the "win-win", please feel free to contact us.

Certifications

Payment & Shippment

1. We prefer payment through T/T, L/C, D/P, Western Union and Paypal are also workable.

2. By courier, like DHL, UPS, Fedex. That is door to door, usually 5-7 days to arrive.

By air transport, usually 3-4 days to arrive.

By sea transport, usually 15-30 days to arrive.

If your delivery time is very urgent, we suggest you choose by courier or by air transport. That is suitable for the Samples or the small qty goods.

If your delivery time is not very urgent, we suggest you choose by sea transport, it is very cheaper.