-

Needle Petroleum Coke For Electrode Production

Needle Petroleum Coke For Electrode Production represents roughly 80 percent of worldwide petcoke production, and Speedchem is the worldwide leader in fuel grade petcoke sourcing and sales, handling more than 11 million tons per year. Needle Petroleum Coke For Electrode Production is typically very high in heating value (BTUs per pound), produces virtually no ash when burned, and is most commonly used in electric power plants and cement kilns

Send Email Details -

Cold Ramming Carbon Electrode Paste For Ferro Silicon

the production of Hengqiao electrode paste also needs to improve the sintering speed of the electrode through the adjustment of the formula, such as appropriately adding graphite materials with good conductivity and heat transfer performance in the formula Conduction heat obtained in the furnace to speed up the roasting speed, while trying to reduce the consumption of the electrode to reduce the speed of the electrode lowering can also achieve the matching of electrode consumption and roasting.

Send Email Details -

Fuel Grade Calcined Pet Coke For Iron Foundry

Fuel Grade Calcined Pet Coke For Iron Foundry is a high purity carbon material produced by heating green petroleum coke to drive off moisture, volatile matter, and impurities and to increase its electrical conductivity

Send Email Details -

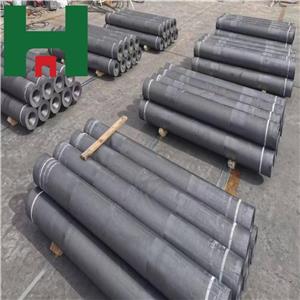

UHP HP SHP high grades graphite electrodes hengqiao supply

Graphite electrodes are manufactured using high-quality petroleum coke and needle coke as primary raw materials. These materials undergo blending and baking processes to create the desired electrode properties.

Send Email Details -

customized size carbon electrodes manufacture supply

Carbon electrodes are manufactured using high-quality raw materials such as petroleum coke and coal tar pitch. These materials undergo a meticulous blending process to achieve the desired composition. The resultant paste is shaped, baked, and impregnated to produce durable and conductive carbon electrodes for various industrial applications.

Send Email Details -

Graphite Electrodes Ultra High Power Electrode Manufacture Supply

The quality of the graphite electrode itself affects the consumption ratio. Nowadays, the smelting and process of electric arc furnaces have higher requirements on the anti-oxidation performance and thermal shock resistance of graphite electrodes. Moreover, the high consumption caused by fluctuations in quality is greatly concerned by users. Therefore, the homogeneity and stability of graphite electrode are the most important factors to determine the consumption.

Send Email Details -

Strong Electrical Conductivity Carbon Electrodes Manufacture Direct Sale

Carbon electrode is a conductive material produced with anthracite and metallurgical coke as the main raw materials (sometimes with a small amount of natural graphite or graphitized broken).

Send Email Details -

Steel Casting HP Extruded Carbon Graphite Electrode with Nipples

Graphite electrode, with above irreplaceable performance advantages, plays an indispensable role in the high temperature manufacturing field such as iron and steel smelting, electrolytic aluminum, ferroalloy, calcium carbide, industrial silicon and yellow phosphorus smeltingses.

Send Email Details