-

Briquettes Electrode Paste Used in Ferroalloy Plants Saf Furnaces

Electrode paste, also known as anode paste, self-baking paste or electrode carbon paste, is often used in ore-smelting electric furnace as conducting material.

Send Email Details -

Gread Quality Low Sulphur Foundry Coke Shandong Factory Direct Sale

Coke is a type of fuel obtained in coking plants by coking, i.e. burning hard coal at a temperature of 600-1200 ° C in a special coke oven using flue gases, with limited oxygen access. It is a fuel with a higher calorific value than regular fossil coal. There are several types of coke: blast furnace, metallurgical, foundry and heating coke. Coke is used primarily in the smelting of iron in blast furnaces in smelters, but it is also used as a high-quality fuel for heating boilers (in boiler rooms, workshops and households), as well as in metal foundries.

Send Email Details -

Low Sulphur Carbon Electrode Paste for Ferroalloy

Electrode Carbon Paste also known as Soderberg Electrode Paste made from mix of fractions of Calcined Petroleum Coke (CPC) or Electrically Calcined Anthracite Coal (ECA coal) mixed with Coal Tar Pitch as Binder and Anthracene Oil at a predetermined temperature. It is used as conductor in sub merged arc furnace under self Baking process while manufacturing different types of Ferro Alloys and Calcium Carbides.

Send Email Details -

China Factory Provide Free Sample Anthracite Coal Activated Carbon

CPC is a high carbon content material used in several industrial processes including Aluminum smelting, Steel recarburization, Titanium dioxide production, Graphite electrode production and other specialty uses.

Send Email Details -

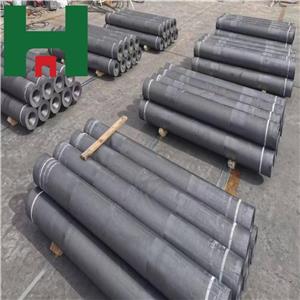

Carbon Electrode High Compression Strength Wholesale Price

Carbon electrodes have the bulk amount of free electrons that are free for transfer and have the ability as a conductor. These reasons make it suitable to use in electrolysis. Carbon not only has an efficient conductivity property, but it also has an extremely high melting point. This implies it can be used to help in an extensive range of complex reactions.

Send Email Details -

Low Consumption Carbon Electrode High Resistivity Electrodes Hot Sale Supplys

Carbon electrode is not a metal, technically a semi-metal, but conducts electricity well enough under the right conditions to be useful as a conductor in some circumstances. It’s also chemically less susceptible to the degrading effects of some electrochemical reactions, being fairly chemically inert, and is far cheaper than using more chemically inert electrodes made from platinum-group metals, which range from more expensive than gold in the case of platinum, to more expensive than everything, in the case of most other platinum-group elements.

Send Email Details -

China Factory Supplier Calcined Petroleum Coke for Steelmaking

The rising use of green petroleum coke in electronic and ceramics industries is expected to boost the growth of the global green petroleum coke & calcined petroleum coke market.

Send Email Details -

Carbon Anode Butts Strong Electrical Conductivity Aluminium

Using petroleum coke, asphalt as aggregate and coal tar pitch as binder, the carbon block produced by kneading, forming and roasting is called anode carbon block, which is used as the anode material of prebaked cell. The calcined carbon block has a stable geometric shape. So it is also called preparatory anode carbon block. And it’s also known as carbon anode for aluminum electrolysis. As an electrode, the aluminum reduction cell with prebaked anode carbon block is called prebaked anode cell for short.

Send Email Details